Shaliteink’s Yellow Plastisol Ink is engineered for optimal performance in textile and garment printing. As a main Screen Printing Ink Manufacturer, we provide terrific, regular inks designed to meet the needs of large-scale garment manufacturing. This versatile ink is right for colourful, durable prints on a lot of fabrics, which includes cotton, polyester, and blends.

Our Yellow Plastisol Ink is especially formulated to provide superior shade accuracy and vibrant tones. Known for its superb opacity, this ink ensures that your prints are formidable and stand out, even on darkish fabrics. The amazing shade replica ensures that designs are faithfully rendered, making it a dependable preference for high-quantity, professional printing.

Key Features & Benefits:

- Consistent Color Results: Rigorously formulated to guarantee colorfastness and minimal lot-to-lot deviation, minimizing rework and maximizing throughput for high-value contracts.

- Rapid Curing: Cures fully at 320°F/160°C in as little as 45–60 seconds, optimizing energy use and boosting per-hour output on automatic and manual print lines.

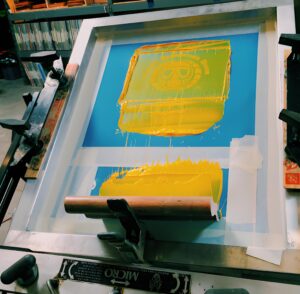

- Equipment Compatibility: Flows easily through 110-305 mesh counts, resists screen dry-in, and integrates seamlessly with advanced presses or flash units—ideal for today’s automated, large-scale textile factories.

- Superior Wash & Rub Fastness: Exceeds key standards for industrial laundering; holds color and hand feel through 50+ commercial wash cycles, supporting your clients’ durability requirements.

- OEKO-TEX & ISO Certified: Fully compliant with major global safety and eco-standards, supporting your need for certified supply chains and credible end-customer claims.

- Cost-Efficiency: Flexible bulk packaging and tiered discount programs help you control unit costs, supporting high-volume, margin-sensitive contract fulfillment.

- Outstanding Opacity: Single-hit coverage on both light and dark garments means less ink, less labor, and cleaner prints, even on poly-cotton or performance blends.

- Easy Clean-Up: Formulated for rapid breakdown with standard screen cleaning solutions; reduces downtime during color changes or job switches, letting you respond agilely to new orders