Product Description

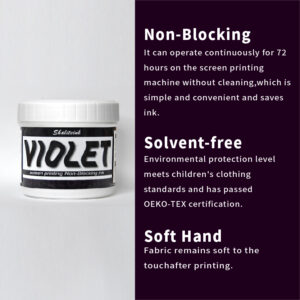

Solvent-free, PVC-free, environmentally friendly ink, specially designed for natural fiber fabrics such as pure cotton and cotton blends, and has passed OEKO-TEX 100 baby-grade safety certification. It combines environmental safety with excellent printing performance, and is superior to traditional water-based inks in all aspects. It is the preferred product for high-end cotton fabric printing.

Five core advantages

| Comparison Dimensions | Non Blocking Ink | Traditional water-based ink |

| Hazardous substances | Solvent-free, PVC-free, suitable for skin contact with babies and mothers | Some contain APEO, formaldehyde release, dark ink may have heavy metal residues |

| Environmental certification | OEKO-TEX 100 baby-grade certified | Only some of them have passed the general environmental certification, and baby products need additional testing |

| VOC emissions | Very low VOC (<5g/L), no irritating odor in the workshop | VOC is high (20-50g/L), ventilation equipment is required for long-term operation |

Cotton printing performance is fully upgraded

① Color fastness: No fading after 100 washes (far exceeding the standard of 30 washes for water-based ink)

Dry rubbing fastness: Grade 4-5 (AATCC standard)

Wet rubbing fastness: Grade 4 (AATCC standard)

Soap washing fastness: Grade 4 (GB/T 3921-2008) Comparison: The edges of water-based ink tend to turn white after 30 washes, and dark patterns appear “white”.

② Hiding power: Dark cotton can also print “bright white”

White ink hiding power: ≥95% (20μm film thickness), showing pure white on dark blue cotton

Water-based ink requires primer or multiple printings, and white is transparent, and dark substrates tend to appear gray. Case: A trendy brand sweater uses this product to print a white LOGO, and the contrast on the black substrate is increased by 30%, making the visual effect sharper.

③ Softness of touch: comparable to the “original texture of fabric”

Film thickness after curing: 15-20μm, delicate touch, no cracks when folded

After the water-based ink is dried, the film thickness is 30-50μm, with high stiffness, and the hand feels harder after multiple washings. Actual measurement: After printing on cotton cloth of the same weight, the touch score of this product (out of 5 points) is 4.8 points, while the water-based ink is only 3.2 points.

④ Elastic adaptation: 200% stretch without breaking (special for stretch cotton)

Elongation at break: ≥200% (ASTM D412), suitable for stretching scenes such as yoga pants and stretch T-shirts

Water-based ink will crack when stretched by 50%, and elastic agent needs to be added, but the cost increases by 20%

Application scenarios

1. Infant and toddler clothing: safety first, mothers rest assured

Applicable to: baby crawling clothes, bibs, children’s underwear

Core value: passed the baby skin contact safety certification, no risk of plasticizer migration, resistant to frequent washing and no fading, protecting the baby’s delicate skin.

2. High-end fashion: a double breakthrough in texture and design

Applicable to: designer brand dresses, luxury sweatshirts, high-count cotton shirts

Core value: delicate touch does not destroy the high-end feel of the fabric, high covering power realizes creative printing of dark base fabrics, and helps designers achieve the “what you see is what you get” pattern effect.

3. Functional clothing: a perfect combination of performance and function

Applicable to: sports quick-drying clothes, outdoor assault clothes, yoga clothes

Core value: high elasticity without cracking, sweat stains and water washing resistance, suitable for fabric stretch performance, long-term exercise friction without falling off, while meeting functionality and aesthetics.

4. Cultural and creative products: long-term preservation, timeless

Applicable: museum IP cultural and creative T-shirts, band tour commemorative shirts, retro and distressed sweatshirts

Core value: UV resistant, long-term collection without fading, clear pattern details, becoming a “wearable work of art”.

Three reasons to choose us

1. Professional cotton cloth solution, refuse “general” compromise

Optimize the formula according to the characteristics of cotton fiber, solve the problem of “cotton cloth sticking hair and poor air permeability” of traditional thermosetting ink, the ink film layer is more tightly combined with the fiber, and the air permeability is improved by 40% (ASTM D737 standard).

2. Full technical escort, 0 experience can quickly get started

Provide “Cotton Cloth Printing Process Manual” (including screen mesh, scraper angle, curing parameter recommendations)

Free on-site equipment debugging, 24-hour online technical support, solve “color difference, sticking, insufficient curing” and other pain points.

3. Environmental protection and compliance double insurance, help brand premium

Provide a full set of certification documents (OEKO-TEX, CPSIA, REACH) to help customers pass brand factory inspection

The terminal product can be marked with the exclusive logo of “PVC-free environmentally friendly ink” to enhance consumer trust, with a premium space of 5%-15%.